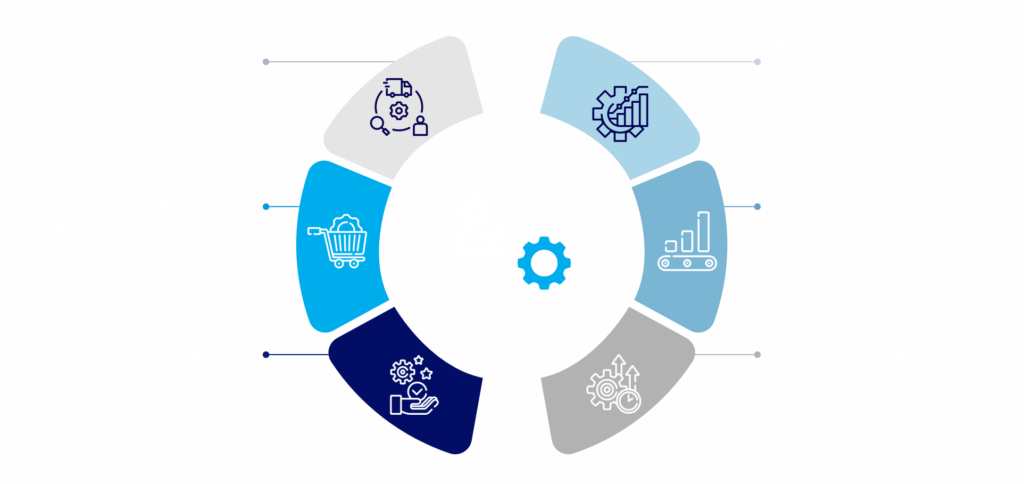

For the past decade, Mirow has worked alongside COOs and operations managers to increase its clients’ profitability and competitiveness. Leveraging proprietary methodologies, we assist companies in designing their supply chain strategy by identifying opportunities and implementing improvements in supply chains, procurement, and manufacturing processes.

Our Operations practice also helps companies optimize their costs, expenses, and investments, enabling rapid financial gains.

Supply chain strategy

Different analyses support the development of an operations strategy. We assess the maturity of the company’s operations and supply chain processes, identifying the most significatn opportunities for improvement. The strategy involves establishing an integrated sales and operations plan (S&OP), ensuring greater alignment between market demand, procurement, and production; giving management greater governance. We translate corporate strategy into an operations strategy, supporting decisions on internalizing processes versus outsourcing them. Lastly, we assist in mapping and revising processes, along with defining their monitoring metrics.

Network and inventory optimizations

Depending on the supply chain strategy adopted, various stock-balancing strategies may be necessary in production chains. We have developed methodologies to define optimal inventory levels based on the desired service levels for our clients’ operations, and work to optimize storage and distribution footprints. We aslo review inbound and outbound logistics flows, assisting in determining the best mix of transportation modes and identifying opportunities to reduce freight costs.

Procurement

Procurement excellence involves more than just cost-cutting; it’s about ensuring the expected level of service for all areas and enhancing collaboration between suppliers and internal functions. To this end, we conduct strategic sourcing projects to evaluate spending and identify opportunities for efficiency gains. This involves identifying and approving the best supply alternatives, whether local, regional, or global. Finally, we refine this new purchasing strategy within the organization, offering training and worskshops to enhance capabilities.

Manufacturing

Every industrial company wants to become the next “Toyota” and have simple, flexible production, but few manage to achieve this. To deliver manufacturing excellence, we translate corporate and operations strategy into the production process. We support our clients in identifying their business objectives, evaluating the technology employed in their plants and how it can be elevated to the next level. To this end, we work hand in hand to create a strong culture of continuous improvement and performance management at all levels of the organization.

Service operations

Determining the right level of low-cost service for each segment is a common challenge in service operations, whether for retailerers, for a financial institution’s call center, or support functions such as finance or HR. We assist in mapping processes and organizational structures of functional areas, ensuring greater adherence to corporate strategy, which can be deployed in shared service center (SSC) and center of excellence (CoE) projects.

Capital productivity

We help our clients in capital-intensive industries to maximize their individual projects, as well as entire project portfolios, from conception to execution.

Cases

Examples of work

We developed a cost performance plan for a large wood panels player with an estimated gain of US$15 million per year

We transformed the S&OP and inventory management of a commercial vehicle manufacturer, generating US$20-30 million of EBIT per year